Barrel-Pump Unit

Key words:

Condensing Unit

Classification:

Condensing Unit

It has high heat exchange efficiency for the evaporator, good cooling effect, and can exert the heat transfer efficiency of the entire evaporation area of the evaporator; and due to the washing of a large amount of refrigerant, the evaporator tube wall is not easy to form an oil film, and the bottom is not easy to accumulate oil.

Barrel-Pump Unit

Designed for preservation, freezing, refrigeration and design, with refrigeration, ventilation and other effects;

The shell is made of high quality steel plate, surface spray, corrosion resistance, beautiful appearance;

● The coil adopts the wrong arrangement method, uses the mechanical expansion tube, uses the copper tube and the aluminum sheet to combine closely, the heat exchange effect is good; The high-quality stainless steel electric heating tube is evenly distributed in the plate

In the tube, the defrosting effect is good; the electric heating tube defrosting adopts the electric heating aluminum sleeve and the fin hole tightly, which is easy to dissipate heat and has a long service life;

● The design width of the air cooler is reasonable, and the spacing between the fan blade and the aluminum fin is greater than 1/3 of the fan blade diameter to ensure sufficient effective air volume;

● Long-distance air supply duct can be used according to customer requirements.

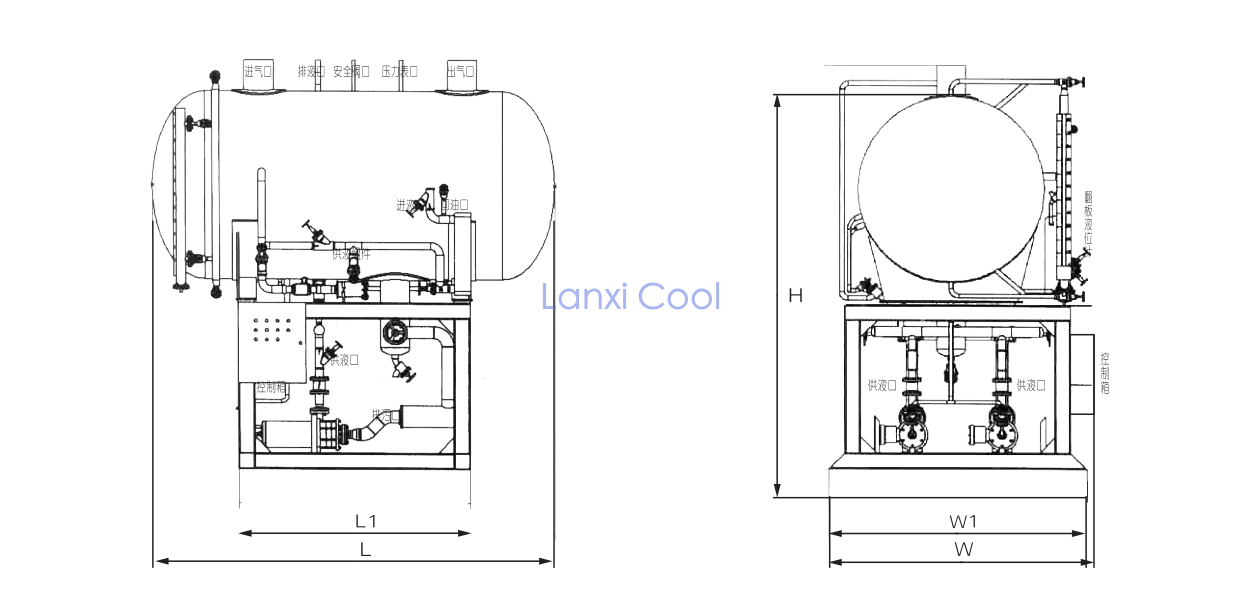

Overall dimensions:

Standard configuration:

Low-pressure circulating barrel, shielding pump, flap level gauge, stop valve, throttle valve, solenoid valve, safety valve, liquid filter, electric control box and frame.

Fluorine pump for liquid characteristics:

It has high heat exchange efficiency for the evaporator, good cooling effect, and can exert the heat transfer efficiency of the entire evaporation area of the evaporator; and due to the washing of a large amount of refrigerant, the evaporator tube wall is not easy to form an oil film, and the bottom is not easy to accumulate oil. Stain, so that the heat transfer coefficient of the tube wall can be improved. However, the direct expansion liquid supply is insufficient, and all the ends of the aluminum row become superheated gas, which will not only reduce the utilization rate of the evaporation area and supply too much liquid, but also easily cause the wet stroke of the refrigeration compressor, which cannot guarantee the safe operation of the refrigeration device. In addition, the existence of two-phase fluid greatly increases the resistance loss of the liquid supply pipeline and also reduces the cooling effect of the evaporator. Therefore, the same evaporation area of the evaporator, the cooling effect of the fluorine pump liquid supply is more than 20% higher than that of the direct expansion liquid supply.

It can ensure long-distance liquid supply. Using the action of the pump, part of the resistance loss in the system can be overcome to achieve long-distance liquid supply.

The operation of the system is simple and reliable, which is convenient for centralized control and automation, and the operating conditions of the refrigeration compressor are improved. Fluorine pump for liquid refrigeration system, in the warehouse heat load without large fluctuations, fluorine barrel liquid level is more stable, can maintain the normal operation of the pump.

Can be hot fluorine defrosting, simple and efficient.

Scope of application:

Low-temperature cold storage pipe and quick-freezing cold storage shelf pipe, quick-freezing tunnel, garlic storage, fruit and vegetable pre-cooling and large-scale ice-making projects.

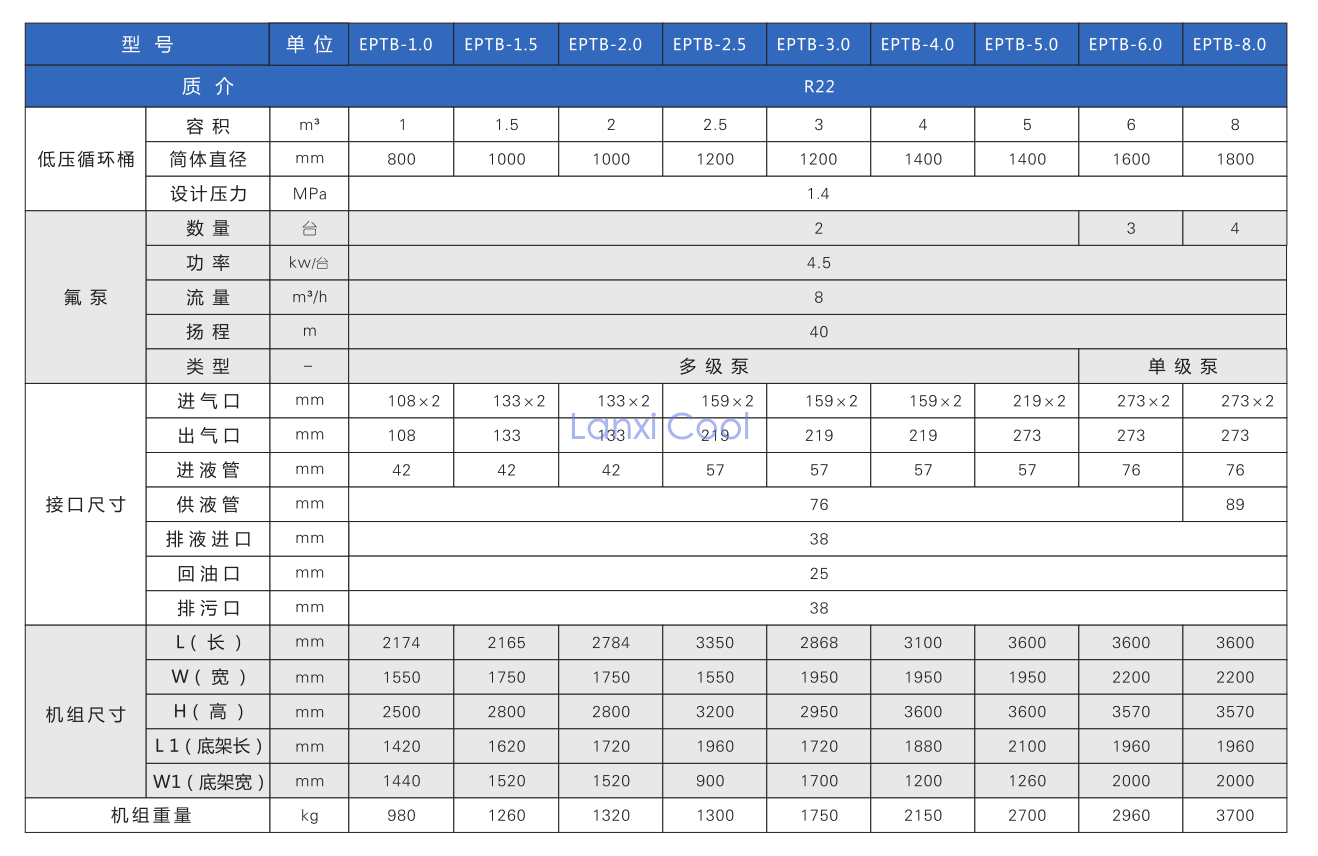

Technical parameters:

Previous Page

Next Page

Related Products

online message

Please leave your contact information for a free quote