Evaporative condenser

Key words:

Products

Evaporative Condenser

Classification:

Products

Evaporative Condenser

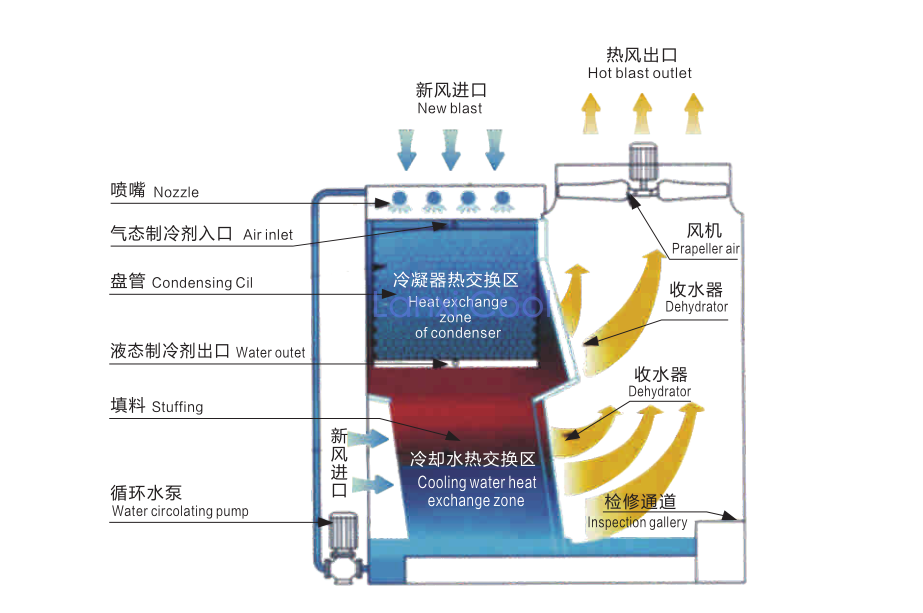

LX products use the technology of wind and water co-flow mixed flow secondary heat exchange coil and PVC filler combination to achieve heat exchange.

Evaporative condenser

Designed for preservation, freezing, refrigeration and design, with refrigeration, ventilation and other effects;

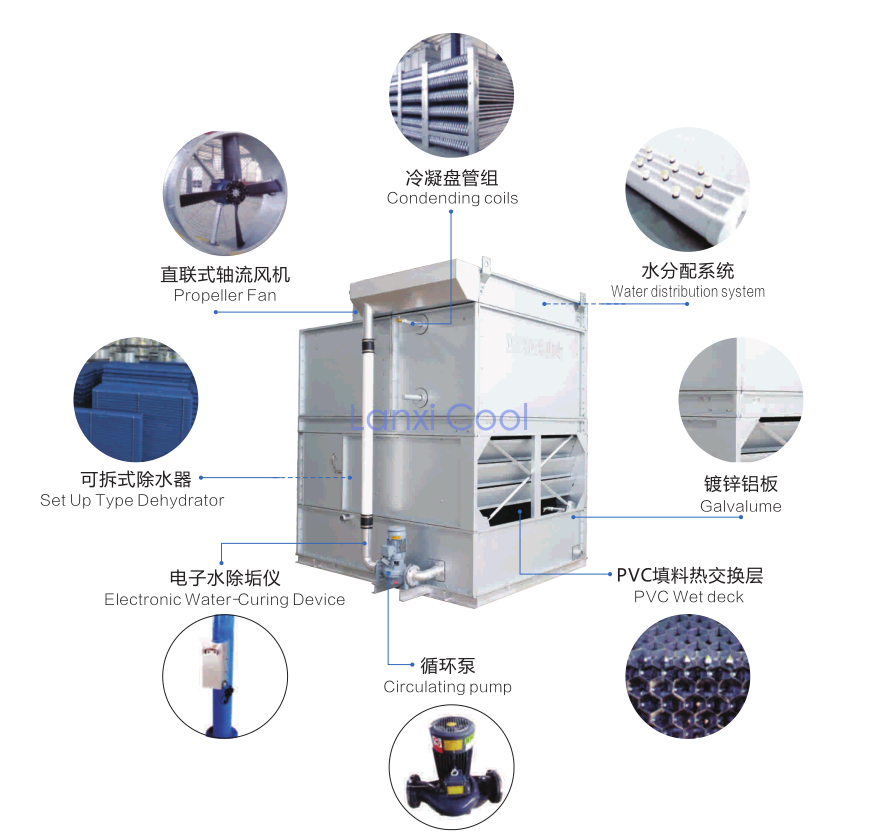

The shell is made of high quality steel plate, surface spray, corrosion resistance, beautiful appearance;

● The coil adopts the wrong arrangement method, uses the mechanical expansion tube, uses the copper tube and the aluminum sheet to combine closely, the heat exchange effect is good; The high-quality stainless steel electric heating tube is evenly distributed in the plate

In the tube, the defrosting effect is good; the electric heating tube defrosting adopts the electric heating aluminum sleeve and the fin hole tightly, which is easy to dissipate heat and has a long service life;

● The design width of the air cooler is reasonable, and the spacing between the fan blade and the aluminum fin is greater than 1/3 of the fan blade diameter to ensure sufficient effective air volume;

● Long-distance air supply duct can be used according to customer requirements.

Key features:

LX products use the technology of wind and water co-flow mixed flow secondary heat exchange coil and PVC filler combination to achieve heat exchange. Since the air and spray water flow through the coil in the same direction, the spray water can evenly cover the surface of the coil, and the surface of the coil is wet. Compared with the reverse structure of feng shui, the formation of dry points and scale on the coil wall is reduced.

Low operating cost, energy saving and environmental protection:

Due to the unique structure of this product, as well as its unique high thermal performance, so the condensing temperature is low, the operation of electricity saving, water saving, low noise does not pollute the environment and low maintenance costs, is a real energy-saving and environmentally friendly products.

Realize maintenance without shutdown:

LX products can not stop the case of floating ball valve, filter for maintenance. Because the product adopts the same direction design structure of feng shui, the nozzle and coil can be easily checked when the equipment is running.

Easy maintenance:

Using humanized structure design, large access door, spacious internal space, maintenance personnel in the product can easily carry out a variety of maintenance work.

Tilted collecting pool for easy cleaning:

The structural design that the bottom of the sump is inclined to the end of the sewage outlet can easily remove the sewage and precipitated impurities in the sump.

Working principle:

LX evaporative condenser is a kind of heat exchange equipment developed by improving the heat exchange technology at home and abroad.

Reliable fastening elements:

The box of LX product is connected by stainless steel (304) bolts, and its corrosion resistance is unmatched by ordinary steel bolts, which also brings effective guarantee for the long-term stable work of evaporative condensation.

Low failure rate:

Fans and pumps are made of high quality bearings, in addition to no other running wear parts. The fan adopts a direct-coupled structure, without the transmission loss caused by the pulley structure. Low noise and low failure rate.

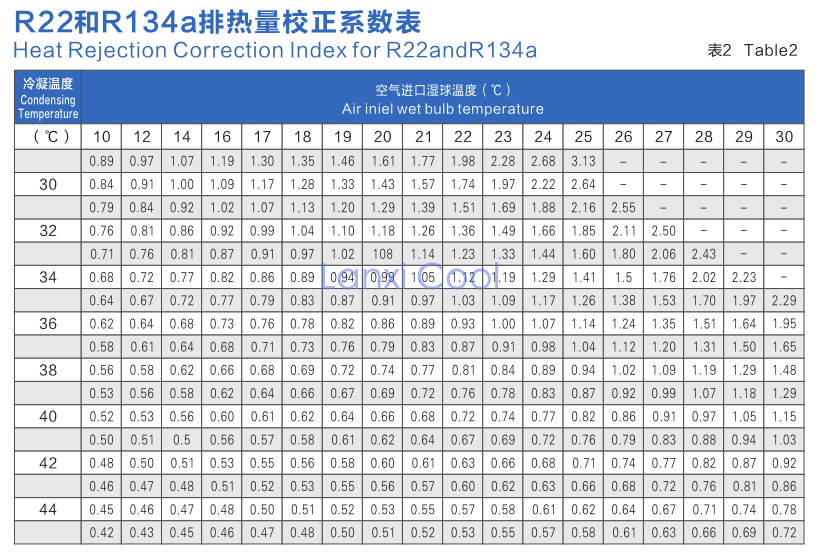

Selection method and correction coefficient table:

Selection method guidance:

1. Confirm the use conditions: condensation temperature, wet bulb temperature.

2. Calculate the total heat discharged by the system to the condenser.

3. Look up Table 2 or Table 3 and select the heat removal correction factor.

4. The total heat discharge multiplied by the correction coefficient is the condensation load under the operating conditions.

5. Look up Table 1 for selection and select the heat discharge amount greater than or equal to the corrected heat discharge amount data.

For example:

1. Conditions of use: condensation temperature 36 ℃, wet bulb temperature 29 ℃

2. The total exhaust heat of ammonia refrigeration system is 940KW. (Compressor refrigerating capacity Compressor shaft power = total heat discharge 3. Look up Table 2, the heat discharge correction coefficient is 1.35. 4. Calculate the actual load of the condenser: 940KWX1.35 = 1269KW.

5. Look up Table 1 and select LX-1285B type evaporative condenser with heat discharge> 1269KW

Selection method note:

1. The parameters in the following specifications are only for reference and modification without notice.

2. Charge quantity index The charge quantity of nitrogen (NH) under standard operating conditions shall be calculated separately for other refrigerants.

3. The operating weight in the table is the weight of the equipment plus the amount of refrigerant and the weight of the water stored in the bottom water tray.

4. Users non-standard special requirements, can be designed and manufactured on behalf.

5. The nominal working condition heat discharge in the table refers to the data of condensation temperature Tκ = 36 ℃ and air inlet temperature Ts = 26 ℃.

Previous Page

Previous Page

Related Products

online message

Please leave your contact information for a free quote